Open and Accurate Air Quality Monitors

We design professional, accurate and long-lasting air quality monitors that are open-source and open-hardware so that you have full control on how you want to use the monitor.

Learn Moreby Ethan Brooke on January 15, 2025

In late 2024, we discovered a calibration issue with the Plantower PMS5003 sensors in AirGradient ONE indoor air quality monitors. These sensors read significantly lower PM1.0, PM2.5, and PM10 levels than previously, which often results in these sensors consistently showing zero at low concentrations. We found this issue quite widespread, impacting many batches of PMS5003 sensors.

We spent weeks looking into this issue and documented all of our findings in a blog post here. Please refer to that post if you would like to learn more, including the corrections we applied to improve these sensors. However, since it has become long and is now quite outdated, we wanted to release another update discussing where we stand on this matter and how we will continue moving forward. Here’s a quick summary of the issue so far.

While we have now rolled out corrections for all of the sensor batches we’ve encountered with these new calibrations (these can be applied on the dashboard), we have a few updates to these findings. Perhaps most importantly, we believe this was not an issue at Plantower (or faulty sensors) but rather a change to its default calibration method. This, unfortunately, means that even new batches of these sensors are similarly calibrated, and show the same behaviour. Again, despite this different calibration, the sensors perform within their specifications (± 10μg/m3), but we believe they were more accurate before these changes.

With that said, through extensive testing, we’ve found that corrections we’ve developed in-house have brought the sensors to the same accuracy level they had before. In fact, in some of our testing, we have even found our corrections to improve the performance of the Plantower PMS5003, and we have been able to verify this by comparing the readings to our reference instruments in the AirGradient testing lab. While the new calibration caught us off guard initially, we believe we have addressed this problem correctly, and we are very excited by the prospect of calibrating these sensors ourselves to improve performance even further.

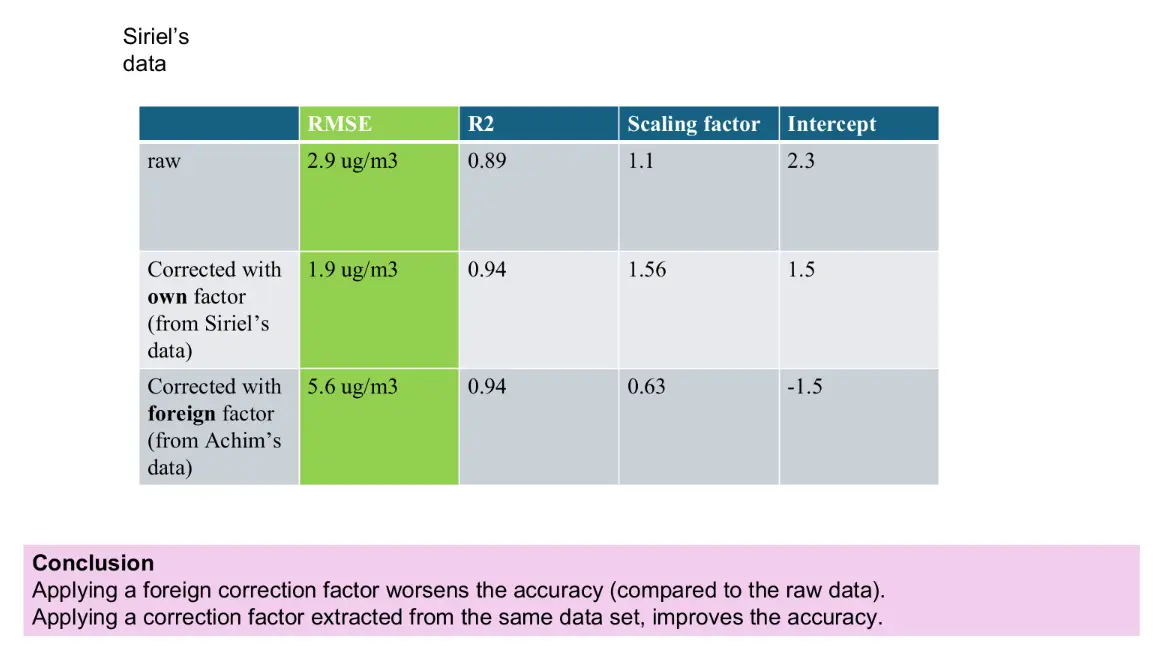

A table showing raw data and the improved R-squared value with correction factors applied. For the full context and explanation behind this table, please refer to our previous article on the topic.

Although we have already implemented these corrections on our dashboard, we still have some work to do. Currently, the API still reports uncorrected values, meaning that this issue may still be present in data obtained through the API.

We have already made strides to address this issue and to pick up any similar issues that may arise in the future. We’re confident in these improvements and very excited about the prospect of implementing corrections and calibrations, as we believe this can allow us to improve the accuracy of our devices even further. We believe that this new calibration process also gives us much more control over our monitor accuracy than other manufacturers, who don’t have the capabilities or who don’t offer custom calibrations and are, instead, reliant on calibrations created by the sensor manufacturers.

Going forward, we are going to start assigning individual correction factors to each unit that goes through our testing procedure. This will allow us to not only improve performance on a per-batch level but also go as far as to calibrate every single unit we sell individually. While we are still setting up the procedure for this, we are very excited to begin soon!

Read more about how we discovered and worked through this issue.

Curious about upcoming webinars, company updates, and the latest air quality trends? Sign up for our weekly newsletter and get the inside scoop delivered straight to your inbox.

Join our Newsletter

We design professional, accurate and long-lasting air quality monitors that are open-source and open-hardware so that you have full control on how you want to use the monitor.

Learn More